Classified Ads

| Name : |

PINNACLE 5-AXIS MACHINING CENTER AX450 5轴加工中心 |

|

|

| |

Description : Flexible application on robust structure

Simple and compact design

to solve your most complicated machining jobs. | | | | High-Tech Expertise in 5-axis Machining | | | The major components are made from high quality Meehanite cast iron, which are annealed and stress-relieved before machining. The spindle with entire headstock assembly is counter-balanced by pneumatic system to minimize the column and headstock vibration during acceleration / deceleration .

The 5-axis synchronized machining allows complicated work pieces to be finished in just one setup, and it increases machining efficiency and accuracy, also reduces machine idle time.

Pinnacle AX 320 / AX 450 are your best choice for producing aerospace components, medical equipment and any parts with multiple curved faces.

AX320/ AX450 are proven to be super machines for high efficiency and accuracy. |

| | Each Pinnacle machine is subject to dynamic and static accuracy tests. Pinnacle machine accuracy meets ISO 10791 VDI 3441, ISO 230, JIS B6388 and ASMEB5 standards. | | | - 760 x 610 x 560 mm Travel

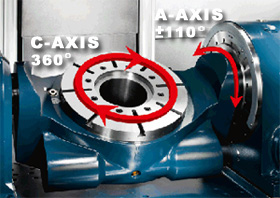

- A Axis Tilt 220° ((±110°)

- C Axis Rotary 360°

- Rapid Feedrate 30/30/24

- 9/12 Kw Spindle Motor

- ISO40 Spindle Taper

- X, Y & Z Axis Linear Way

|

|

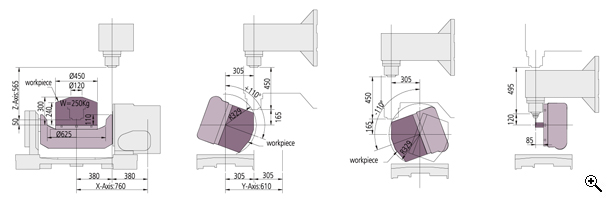

| | | High-Tech Expertise in 5-axis Rotary Table |  | - Rotary Table diameter Ø320 / Ø450mm

- Table rotation and tilting are driven by servo motor

- Positioning accuracy, A/C-axis: 15"/10"

- Repeatability accuracy, A/C-axis: 10"/15"

|

|

| | | 3+2 = ∞

Infinite Solutions

Rigid ● Stable ● Accurate | | | 3 linear axes X/Y/Z plus rotary and titling axes A/C offers almost infinite solutions to your 5-axis or multiple faces machining jobs. The two-in-one rotary/titling table features easy maintenance and low service cost.

AX320 A-axis swivels 150°and AX450 swivels 220° to optimize machining space and allows complex workpiece to be finished in just one setup and reducing cycle time. | | | | Robust Structure ensures long term accuracy, year after year. |

|

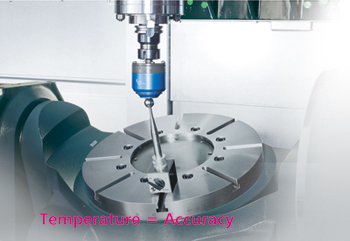

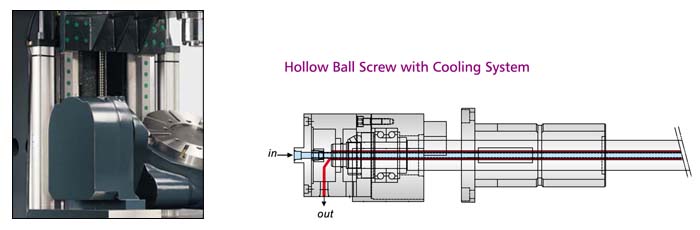

| | | | | It is all about Temperature control | | |  | | The machine's actual cutting quality and accuracy relies on the temperature control techniques. No machine can be called precision machinery without mastering this critical know-how. Pinnacle 5-axes machines employ chiller to keep the headstock in a constant and stable temperature level, and depended on customer's work shop condition, coolant through ball screws are available to minimize the temperature variation. |

|

| Outstanding craftsmanship | | |  |

| | Oil cooling through ball screws on X, Y, Z axis minimizes thermal deformation and backlash, while ensuring smooth motion during rapid traverse. |

|

| | | PNEUMATIC BALANCE SYSTEM | - The Z-axis is pneumatic counter-balanced via high response pneumatic cylinders. Plus an air reservoir tank to boost the balancing performance, ensuring fast and stable Z-axis movement, giving high surface finish.

|

| COOLING SYSTEM TO SPINDLE | - The spindle oil cooler permits the spindle to keep a constant temperature running and ensures long service life. It also provides high efficiency machining and high accuracy.

| | | | LINEAR ROLLER GUIDEWAY |  | - X/Y/Z axes adopt roller guideways for optimum rigidity and speed 6 rolling shoes on X/Z axes minimize damping effect.

|

|

| | | RIGID MACHINE BASE AND SADDLE |  | - Drive motors direct coupled with pretensioned and oversized ballscrews to ensure cutting quality.

|

|

Each Pinnacle machine is subject to dynamic and static accuracy tests.

Pinnacle Machine accuracy meets ISO 10791 VDI 3441, ISO 230, JIS B6388 and ASMEB5 standards. |

| Accuracy | | ISO 10791-4 |  | | | Axis Travel | Axis Travel | | | >500mm<800M | >800mm<1250M | | | Bi-directional Positioning | A: | 0.025 | 0.032 | 0.003mm | | Bi-directional Repeatability | R: | 0.015 | 0.018 | 0.003mm | JIS B6336-4 shows the same value as ISO Standard;

P value of VDI / DGQ3441 is equivalent to A of ISO10791-4, and PS is equivalent to R

All values shown above are measured for machine in good air conditoned environments. |

| WORKING CAPACITY AX450 |

|

| | | | | Quality is not a job, it is our attitude. | | | | |  |  |  | | ISO certification | CE certification | All Aspect Quality System | | | | Quality comes not from inspection but from every Pinnacle staff's mentality. The state-of-the-art inspection equipments only help us to prove our attitude and accuracy results. |

| | |

| - CNC CONTROLLER SYSTEM

BX series combine Heidenhain iTNC530 smart controller system that is a user-friendly, reliable and Hi-Tech controller includes DCM (Dynamic Collision Monitoring), TCPM (Tool Center Point Management) and Title & Plane function.

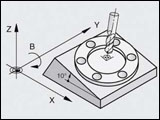

| | |  | - PLANE Function

The PLANE feature makes it easy to define a tilted working plane.

| | |  | - Tilting the Working Plane

With Cycle 19 with swivel heads or tilting tables. You program the operation as usual in the working plane, for example in X/Y. The machine runs the program in a plane that has been tilted by one or more rotary axes with respect to the main plane.

| | |  | - TCPM function (Tool Center Point Management)

In five-axis operations, TCPM function to move the tool reliably on the contour and ensure that the work surface is not damaged. Maintain the position of the tool tip when positioning with tilted axes.

With the aid of the TCPM function, the iTNC 530 automatically corrects the tool path for the machine geometry and the tool length as well as compensates the tool radiusin three dimensions.

| | |  | - Chip Flushing System

Chip flushing system is equipped to remove cutting chips inside of enclosure, which prevents chip accumulation and any possible damage to the linear guideways and ball screws.

| | |  | - DCM (Dynamic Collision Monitoring)

DCM enables you to check for collision in the test run mode before actually machining a part. To avoiding machine dow times. Simulation for a safety process.

| | |  | - Coolant Through Spindle (Option)

20 Bar high pressure pump and sub tank assure CTS system offers the highest efficiency of chip disposal..

| | |  | - Chip Conveyor (Option)

Hinge type or scraper type chip conveyor in front side of machine (able head to left or right) removes chips from machine.

| | |  | - Kinematics Opt. (Option)

Kinematics Opt. is an important component to help you meet these high requirements: With a HEIDENHAIN touch probe inserted, a 3-D touch probe cycle measures your machine's rotary axes fully automatically. The results of measurement are the same, regardless of whether the axis is a rotary table, a tilting table or a swivel head.

|

|

| | SCREW | CHAIN | SCRAPING | | Steel | O | X | O | | Casting Iron | X | O | X | | Aluminum | X | X | O | | Copper | X | X | O | | Mixture | X | O | X | | Not Iron Material | X | O | X |

| Specifications |  | |

| MODEL | AX450 | | TABLE | | | Table Size (mm) | Ø450 | | Travel Ranges (X x Y x Z mm) | 760 x 610 x 560 | | T Slot Size (Size x deg ) | 14 x 45 | | Max. Table Load (0° / 90°g) | 300 / 250 | | Max. Workpiece Size (W x H mm) | Ø600x Ø300 | | Diameter of Table Hole (mm) | Ø171 | | Spindle Nose to Table Surface (mm) | 55~565 | | A Axis, Tilt (deg)/(0.001°) | 220°(±110°) | | C Axis, Rotary (deg)/(0.001°) | 360° | | SPINDLE | | | Tool Shank & Pull Stud | ISO40 | | Spindle Inner Diameter (mm) | Ø70 | | Spindle Speed (rpm) Direct drive | 10000 (12000) | | Spindle Speed (rpm) Built-in | 15000 | | Main Motor (con/30 min Kw) | 9/12 | | AXIS SERVO MOTOR | | | Rapid Feed Rate (X/Y/Z m/min) | 30/30/24 | | Feed Rate (X/Y/Z/ m/min) | 10 | | Feed Rate (A/C rev/min) | 5.5/11.5 | | X Axis Rated Torque (Nm) | 10 | | Y Axis Rated Torque (Nm) | 10 | | Z Axis Rated Torque (Nm) | 10 | | A Axis Rated Torque (Nm) | 10 | | C Axis Rated Torque (Nm) | 10 | | AUTO TOOL CHANGER | | | ATC Type | DISK-24, 30 (Chain-40) | | Cam Type | ARM | | Tool Selection (Bi-direction) | RANDOM | | Tool Storage Capacity (PCs) | 24 (32,40) | | Max. Tool Diameter (mm) | Ø90 (Ø76) | | Max. Tool Length | 300 | | Max. Tool Weight | 8 | | MISCELLANEOUS | | | Air Requirement (Kg/cm2) | 6 | | Hydraulic Requirement (Kg/cm2, L) | 40, 30L | | Voltage | 380 | | Power Requirement (KVA) | 40 | | Coolant Tank Capacity (L) | 300 | | Machine Weight (KGs) | 7000 | | Machine Height (mm) | 2900 | | Floor Space (L x W mm) | 3100 x 2230 | | Packing Size (L x W x H mm) | 3100 x 2230 x 2560 |

| All Specifications And Designs Are Subject To Change Without Notice. |

Company Particular| Company : | PROMACH MACHINERY SDN BHD | | Fax : | +607 3525355 | | Address : | No. 45, Jalan Mutiara Emas 5/16, Taman Mount Austin, 81100 Johor Bahru, Malaysia. | | Email : |  | | Website : | http://promach.com.my | |

|