Classified Ads

| Name : |

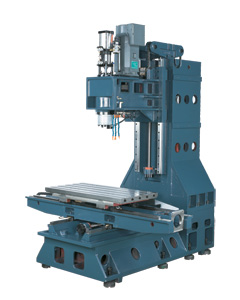

PINNACLE VERTICAL MACHINING CENTER LINEAR WAY SERIES / LV65, LV85, LV105 |

|

|

| |

Description : LV's Designed for Extra Value and Built for Optimum Performance

Linear Way Series

When jobs call for highly efficient machining and when outstanding accuracy is critical, a Pinnacle linear way series vertical machining center is the perfect solution. The three axes move on linear guideways that minimize friction while providing high accuracy of positioning and repeatability. This series are not only suitable for larg-range production line application. It is also ideal for smaller factories and machine shops. If you are serious about increasing machining productivity and profits, the Pinnacle linear way series LV can really help you.

- 650(850)(1020) X 560 x 560 mm Travel

- Rapid Feedrate 30/30/24 m/min

- 10 HP Spindle Motor

- ISO40 Spindle Taper

- Spindle Speed 8,000 rpm, 10,000 rpm (option),

- Direct drive 12,000 rpm (option)

- X, Y & Z Axis Linear Way

The Best Possible Structural Design

Rugged Construction Assures Optimum Rigidity and Stability. The major structural parts are manufactured from high quality Meehanite cast iron (FC-30), hardened to over HB190 and tempered to relieve stress.

High precision and premium quality P class linear quidways way wide block and 35mm (LV65/LV85/LV105) and 45mm (LV96/LV116/LV126)width linear quideways on three axes.

Three axes equipped with class C3 precision and 36mm (LV65/LV85/LV105) and 40mm (LV96/LV116/LV126)diameter ball screws.

Taiwan Patent No.: 177230, China Patent No.: 416211

COUNTER WEIGHT BALANCE SYSTEM

Exclusively designed counter weight balance system. The counter-balance weight moves on a guide shaft to assure movement straightness accuracy. There is no vibration in the forward/backwards and in the right/left directions. This creates superior workpiece surface accuracy to meet various mold machining requirements. Patented in Taiwan and China.

RIGID, PRECISION SPINDLE

ASSURES HIGH QUALITY MACHINING

- Supported by superior precision P4 class bearings, the spindle provides an extra wide range of machining capacity and high speed.

- Floating unclamping system assures tool unclamping force will not transmit to the spindle bearings. It provides stable tool clamping and unclamping with the spindle and extends the spindle bearings' life.

- The spindle is a cartridge-type.

- Choice of various spindle speeds - 8,000, 10,000 and 12,000 rpm.

- The circulating oil cooling system on the spindle head prevents thermal expansion and offers the best precision machining environment.

| Accuracy | | | ISO 10791-4 |  | | | | Axis Travel | Axis Travel | | | Tolerances | | >500mm<800M | >800mm<1250M | | | Bi-directional Positioning | A: | 0.025 | 0.032 | 0.005mm | | Bi-directional Repeatability | R: | 0.015 | 0.018 | 0.005mm | | JIS B6336-4 shows the same value as ISO Standard; | | P value of VDI / DGQ3441 is equivalent to A of ISO10791-4, and PS is equivalent to R | | All values shown above are measured for machine in good air conditoned environments. |

| | Chips Flushing Nozzles | - Coolant flushing nozzles on rear inner wall of guard prevent jam of chips during operation.

|

| | | | |

| | Couplings | - Directly connected with ball screw and AC servo motors, the high precision flexible couplings offer the best rigidity and keeps the accuracy of axial linear assembly under high speed movement.

|

|

| | Coolants Jets Around Spindle | - Improved cooling efficiency on workpiece.

|

|

| | Automatic Lubrication System | - The Lubrication System automatically measures and accurately distributes the oil to the slide ways, ballscrews and bearings.

|

|

| | Control System | - The centralized control panel employs a touch sensing screen for user-friendly operation. The humanized designed control panel has an elegant appearance. Various controllers can be chose - Mitsubishi, Heidenhain, Fanuc and Siemens.

|

|

| | Splash Guard | - The full-enclosed splash guard meets environmental protection and CE requirements. It offers users a comfortable working environment.

|

|

Specifications: | MODEL | LV65 | LV85 | LV105 | | TABLE | | | | | Table Size (mm) | 800 x 510 | 1000 x 510 | 1200 x 510 | | Travel Ranges (X x Y x Z mm) | 650 x 560 x 560 | 850 x 560 x 560 | 1020 x 560 x 560 | | Max. Table Load (kgs) | 600 | 600 | 600 | | Spindle Nose to Table Surface (mm) | 100 ~ 660 | 100 ~ 660 | 100 ~ 660 | | T-slot (Width x Distance x Number mm) | 18 x 100 x 5 | 18 x 100 x 5 | 18 x 100 x 5 | | SPINDLE | | | | | Distance Between Column (mm) | ISO40 | ISO40 | ISO40 | | Spindle Inner Diameter (mm) | Ø70 | Ø70 | Ø70 | | Spindle Center to Column (mm) | 600 | 600 | 600 | | Spindle Speed (rpm) Belt | 60 ~ 8000 (10,000) | 60 ~ 8000 (10,000) | 60 ~ 8000 (10,000) | | Spindle Speed (rpm) Gear | L40 ~ 2000, H2001 ~ 8000 | L40 ~ 2000, H2001 ~ 8000 | L40 ~ 2000, H2001 ~ 8000 | | Spindle Speed (rpm) Direct-Drive | 12000 | 12000 | 12000 | | Draw Bar Force (kgf) | 950 | 950 | 950 | | Main Motor (con/30 min Kw) | 5.5 / 7.5 | 5.5 / 7.5 | 5.5 / 7.5 | | FEED RATE | | | | | Rapid Feed Rate (X/Y/Z m/min) | 30 / 30 / 24 | 30 / 30 / 24 | 30 / 30 / 24 | | Feed Rate (X/Y/Z/ mm/min) | 10000 | 10000 | 10000 | | AXIS SERVOMOTOR | | | | | Mitsubishi X/Y/Z (Kw) | HF353 (3.5) | HF353 (3.5) | HF353 (3.5) | | Fanuc (Kw) | β22/2,000 i (2.5) or α12/3,000 i (3.0) | | Siemens (Kw) | 1FK7 063 (2.9) | 1FK7 063 (2.9) | 1FK7 063 (2.9) | | Fagor (Kw) | FKM64.30A | FKM64.30A | FKM64.30A | | Heidenhain (Kw) | QSY155B (2.47) | QSY155B (2.47) | QSY155B (2.47) | | AUTO TOOL CHANGER | | | | | ATC Type | PLATE / DISK | PLATE / DISK | PLATE / DISK | | Cam Type | GENOVA / DAUL ARM | GENOVA / DAUL ARM | GENOVA / DAUL ARM | | Tool Selection (Bi-direction) | ABSOLUTE / RANDOM | ABSOLUTE / RANDOM | ABSOLUTE / RANDOM | | Tool Storage Capacity (PCs) | 20 / 20 (24) | 20 / 20 (24) | 20 / 20 (24) | | Max. Tool Diameter (mm) | Ø100 / Ø93 (Ø90) | Ø100 / Ø93 (Ø90) | Ø100 / Ø93 (Ø90) | | Max. Tool Length (mm), Weight (kgs) | 250, 8 | 250, 8 | 250, 8 | | MISCELLANEOUS | | | | | Air Requirement (Kg/cm²) | 6 | 6 | 6 | | Voltage | 220 | 220 | 220 | | Power Requirement (KVA) | 15 | 15 | 20 | | Coolant Tank Capacity (L) | 200 | 200 | 200 | | Machine Weight (Kgs) | 4500 | 5200 | 5400 | | Machine Height (mm) | 2650 | 2650 | 2650 | | Floor Space (L x W mm) | 2600 x 2200 | 2600 x 2200 | 3000 x 2200 | | Packing Size (L x W x H mm) | 2650 x 2200 x 2400 | 2650 x 2200 x 2400 | 3050 x 2200 x 2400 |

All Specifications And Designs Are Subject To Change Without Notice. Company Particular| Company : | PROMACH MACHINERY SDN BHD | | Fax : | +607 3525355 | | Address : | No. 45, Jalan Mutiara Emas 5/16, Taman Mount Austin, 81100 Johor Bahru, Malaysia. | | Email : |  | | Website : | http://promach.com.my | |

|